Straightforward assembly of components

Join and release screw connections within seconds

Simple plug and play - no need to screw them in! Reducing the effort involved in assembling components enormously, the threaded lock pins made by Erwin Halder KG help save time and money. Their ingenious operating principle saves you the trouble of turning screws in and out and lets you release and rejoin connections in a quick and easy fashion. Better yet, Halder has now engineered threaded lock pins with axial bearing for all applications that require a greater amount of clamping force.

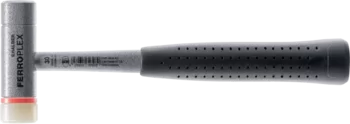

The threaded lock pins – with or without axial bearing – work in a very similar way to the tried-and-tested ball lock pins made by Erwin Halder KG. The main difference is evident on the lower end of the pin: Found on the end of threaded lock pins are self-locking threaded segments – instead of balls – that can be adjusted to fit the corresponding thread size. Releasing them merely requires that the user press the orange aluminium press button at the top end of the pin. The pin can then be easily inserted into the existing threaded hole. When the press button is released, the threaded segments engage in the thread of the part. “Another slight difference: For a firm and secure seat in the bore hole the threaded lock pins require a half turn at the end. To release the pin, simply open it up again with a slight turn and actuate the press button”, adds Kilian Schneck of the Development Department at Erwin Halder KG.

Reduced surface friction = greater clamping force

This operating principle makes threaded lock pins ideal for screwed connections that need to be released and tightened with great frequency e.g. during the assembly of components or while changing wearing parts. “There are, however, also use cases where components need to be frequently clamped with clamping forces that are greater than the forces our standard versions can deliver. This is why we decided to engineer threaded lock pins with axial bearing as well”, explains Kilian Schneck. The increased clamping force is made possible by the minimised surface friction. The new version owes its reduced surface friction to the fact that the strain and the friction only occur from point to point between the bearing balls and the abutting bearing shells. The end result is substantially reduced surface friction. The axial bearing is essential as the friction would otherwise be generated across the entire support surface, which turns as well during tightening. Kilian Schneck: “And, the threaded lock pins offer yet another advantage: They are gentle on the component thanks to the stationary contact surface.”

As we already did with the standard version, we incorporated a slot in the ergonomic handle of the threaded lock pin. This slot allows the user to attach a retaining cable or a clip for a retaining cable, ensuring that the connecting element will not become lost when the pin is released, but stay in the right place at all times. A major asset in your stressful daily work routine!

Available in a multitude of versions

The threaded lock pins with axial bearing are available in versions made from heat-treated steel (HSX 130) and from stainless steel (1.4542). Both offer excellent protection against corrosion and are temperature-resistant up to 80°C. Offering the additional benefit of being weather-resistant, the threaded lock pins made from stainless steel are perfectly suited for outdoor implementations. From stock, Erwin Halder KG delivers the fasteners in the thread sizes M10 and M12 with three different length increments. Thread sizes M8 and M16 are projected to follow shortly.

The threaded lock pins made by Erwin Halder KG expedite the assembly of components dramatically. Equipped with an axial bearing, they are perfect for all applications that require more substantial clamping force.

Excellent protection against corrosion and temperature-resistant up to 80°C – the threaded lock pins with axial bearing are available in versions made from heat-treated steel (photo 2) and from stainless steel (photo 3).

Downloads: