Invaluable tools during rigging

Quick assembly and removal thanks to ball lock pins and lifting pins made by Halder

Rock am Ring, Wacken Open Air, Nature One – after the last two years forced them to go on hiatus, festivals are finally bringing back the pure joy of music this summer. This revival is to the delight of fans and entertainment businesses alike. To blow their audience’s minds, the organisers rely on an extensive range of audio, light and stage installations. Time is of the essence when these installations are assembled and removed. As a consequence, they call for systems that offer quick and effortless handling. Instrumental elements in this regard include such helpful tools as the ball lock pins and lifting pins made by Erwin Halder KG. Thanks to their simple functionality, they are ideally suited for connections which have to be released regularly and offer the added benefit of maximum safety.

Go in – set up – watch concert – take down – get out: The tough job of letting fans enjoy their favourite band to the fullest makes riggers, grounders and technicians work up quite a sweat - both before and after the show. The often elaborate stage structures and equally extensive audio and lighting systems need to be set up and taken down as quickly as possible – because there is next to no time between the different acts of the tour. To ensure that the stage looks neat and tidy during the concert and to position the speakers and spotlights where they can achieve their maximum effect, the individual components are often “floated” – i.e. suspended from special cross-bar structures (rigging). While safety is the top priority, easy handling is desirable as well on account of the tremendous pressure of time. The ball lock pins and lifting pins engineered by Halder offer a synthesis of both of these qualities. They provide a quick and easy way to attach and float such loudspeaker systems as line array speakers. One of the partners who has been relying on the pins made by Erwin Halder KG is d&b audiotechnik GmbH & Co. KG from Backnang.

Ready to float in a few easy steps

As one of the leading businesses in their market, the system supplier for professional sound systems keeps setting new standards in terms of technology and support. The individual products – ranging from line and augmented arrays to point sources, subwoofers, and column loudspeakers to stage monitors, amplifiers, gateways and user interfaces – are painstakingly matched with one another. While exclusive, the resulting connection also offers a uniquely beneficial blend of maximum efficiency, consistency and user friendliness. Also included in this package deal of a system is the software and all accessories.

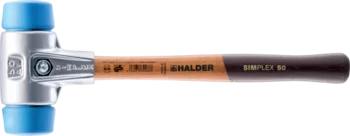

For instance, Halder’s ball lock pins are used as locking pins for the purpose of joining flying adapters between individual speakers in a manner that will ensure the quick and safe set-up of line arrays. The major plus of pins: They can be attached without the need for additional tools - unlike screw connections: To release the self-locking ball at the lower end of the pin, the user merely needs to push the press button at the head of the pin. The pin can then easily be inserted into the existing bore hole. When the press button is released, the balls will lock in place automatically. This creates a secure connection in a quick and simple way and makes it possible to break the connection again with the press of a button.

Countless versions for a variety of requirements

“Our ball lock pins are used across a widely diverse range of applications - with each area posing its own unique set of challenges: For instance, the assembly and disassembly of line arrays, just as many mother types of application, mandate that the ball lock pins not come apart by accident. This requirement drove us to develop our version with a safety handle. As the press button on this special version does not protrude, the ball lock pin is reliably kept from being released inadvertently”, explains Jürgen Rothmund, Standard Parts Sales at Erwin Halder KG.

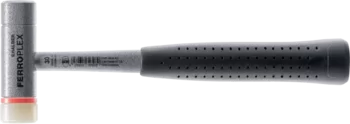

Another example is the quick release pin with button handle, which offers exceptional handling thanks to the compact shape of its handle. These models are complemented by exceedingly inconspicuous versions. They include the ball lock pins with an ergonomic plastic handle, which Erwin Halder KG also offers with a completely black handle. This colour variation is a particularly good choice for all locations where the pin needs to be unobtrusive. What is more, the ball lock pins can be secured with lanyards serving as loss prevention devices or be linked to form a set.

“One common trait is shared by all ball lock pins: They provide for a quick, simple and secure connection. Perfect for setting up and taking down sound systems under tough time constraints”, declares Jürgen Rothmund.

Hoisting single speakers up into the air

One of the use cases for the lifting pins from Erwin Halder KG is the use as so-called flying pins. They serve as connectors that allow for the floating of single loudspeakers or stage monitors with both horizontal and vertical orientation. Sturdy, TÜV-certified and bearing the CE mark, the lifting pins are composed of a pin part and a movable shackle. The lifting element can be fastened simply by inserting it in the prefabricated bores.

Jürgen Rothmund: “In the same way as our ball lock pins, the lifting pins are self-locking. Releasing the self-locking balls at the bottom of the pin, again, merely requires a push of the red press button. Found below the shackle, the press button on the lifting pins slides back to its original position by spring force. This locks the lifting pin in place again. One important detail on our lifting pins: A locking stud prevents the press button from being pushed inadvertently, keeping the pin from being released at the wrong moment.”

Their high-strength pin makes these lifting elements extremely resilient – delivering a maximum lifting capacity of up to 1,000 kg, depending on the model and with up to five times the safety. Better yet, when not under load, the entire lifting pin can be rotated 360°, allowing you to align the shackle perfectly with the direction of force.

Wear-resistant pin

Whether you choose ball lock pins or lifting pins – their tear-resistant materials allow these pins to deliver a long working life and great durability. They are manufactured, for example, from heat-treated steel with manganese phosphate coating or from stainless steel. This furnishes the pins with protection against corrosion and temperature-resistant up to 250°C. Rain or shine – the non-rusting versions stand up to all weather conditions. These attributes make them ideally suited for the job at open-air festivals.

Ball lock pins and lifting pins from Erwin Halder KG offer an easy and secure way to float sound systems. This clears the way for the perfect concert experience.

© d&b audiotechnik

Line arrays can be set up securely and with great ease and speed not least thanks to the ball lock pins made by Halder.

The simple operating principle of the ball lock pins creates the perfect conditions for setting up and taking down sound systems. The model version that comes with a safety handle keeps the connection from coming undone by accident.

Downloads: