-

Products

Product Groups

- Forestry Tools

- Accessories

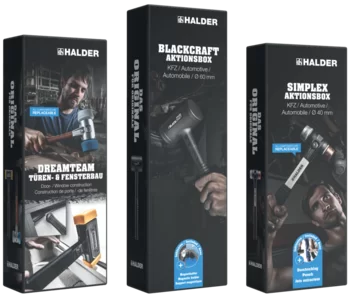

- Promotional Boxes

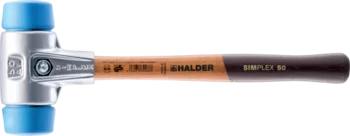

- SIMPLEX soft-face mallets, cast iron housing

- SIMPLEX soft-face mallets, reinforced cast iron housing

- SIMPLEX soft-face mallets, aluminium housing

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up"

- SIMPLEX soft-face mallets, cast iron housing, 50:40

- SIMPLEX soft-face mallets, aluminium housing, 50:40

- SIMPLEX soft-face mallets, cast iron housing, extra short handle

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up", extra short handle

- BASEPLEX soft-face mallets

- SIMPLEX sledge hammers, cast iron housing

- SIMPLEX sledge hammers, reinforced cast iron housing

- SIMPLEX sledge hammers, cast iron housing, with "Stand-Up"

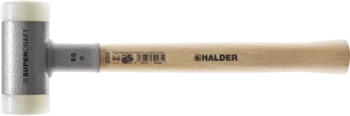

- SUPERCRAFT soft-face mallets

- BLACKCRAFT soft-face mallet

- SECURAL soft-face mallet

- SUPERCRAFT sledge hammers

- MAXXCRAFT Locksmith’s Hammer

- FERROPLEX Combi Hammer

New Items- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with cast iron housing and high-quality wooden handle

- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with aluminium housing and high-quality wooden handle

- SIMPLEX insert, 50:40 TPE-mid, grey

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D60, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D80, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Promotional Box Automotive SIMPLEX soft-face mallet D40, copper / soft metal plus puncher

- BLACKCRAFT Promotional Box Automotive BLACKCRAFT soft-face mallet D60 plus Magnetic Holder

- Promotional Box Dreamteam Door and Window Construction SIMPLEX soft-face mallet 50:40, TPE-soft / TPE-mid and SECURAL plus soft-face mallet

- Service

- Newsroom

- Company

- Contact

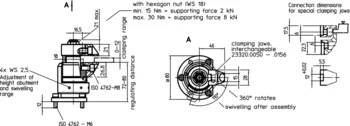

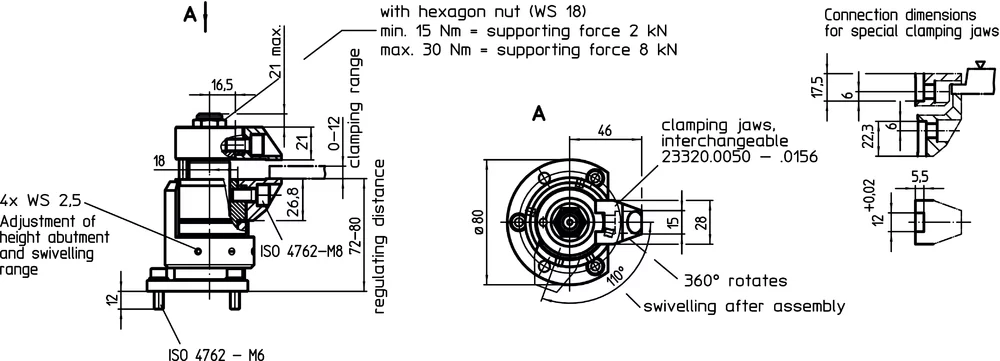

Floating Clamps compact construction, combined clamping and locking M 12

EH 23320.

The floating clamp is used to clamp and support additional clamping points on components.

The benefits of the floating clamp are:

- Avoids vibration during the processing

- Clamps ribs, beads and shackles to reinforce clamped components

- Distortion-free clamping of raw parts

- Compact version with reduced height.

Your selection resulted in 1 hits

[g]

[g]More details

Material

Adjustable body

- Aluminium, red anodised

Body

- Case-hardened steel, nitrided, manganese phosphated and ground

Clamping jaws

- Case-hardened steel, nitrided, manganese phosphated

Notes

For specific clamping situations, the standard clamping jaws supplied can be exchanged or replaced (see catalogue drawing: screw ISO 4762 - M8 - 12.9, M max. = 43 Nm).

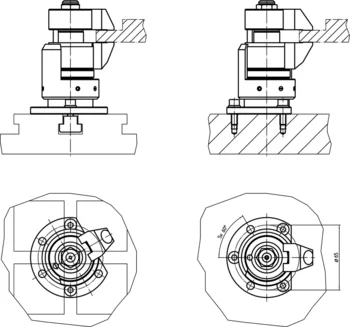

Assembly

- Mount the floating clamp onto the device (mounting holes for M 6, see drawing).

- Adjust the height limit stop and the rotating area with the sleeve, and clamp with set screw (4x WS 2.5). When setting the height limit upwards provide generous clearance (workpiece tolerance).

Operation

- Push the floating clamp downwards.

- Pivot the clamping jaws in as far as possible. The floating clamp contacts the bottom of the workpiece with a slight spring load.

- Tighten the floating clamp with a hexagonal nut (WS 18) having a min. torque of 15 Nm and a maximum torque of 30 Nm. In the clamping process, the workpiece is clamped and simultaneously supported.

- Releasing is done in reverse order.

Accessories

As an accessory, we offer clamping jaws with an increased clamping range, refer to 23320.0050-.0058, as well as pivot jaws, refer to 23320.0148-.0156.

Further products

RoHS compliant

Contains lead - compliant according to exceptions 6a / 6b / 6c.

Contains SVHC substances >0,1% w/w

Contains lead - SVHC list [REACH] as of 23.01.2024.

Contains Proposition 65 substances

Lead can cause cancer and reproductive harm from exposure

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.

Contact Form

Information Material

Information material Standard Parts Information material Workholding Systems Information material Aviation ProductsNews

Have a look to our current new parts:

Locating Pins Eccentric Clamping Clamps Pitbull® Clamps Centering Clamping Mandrels